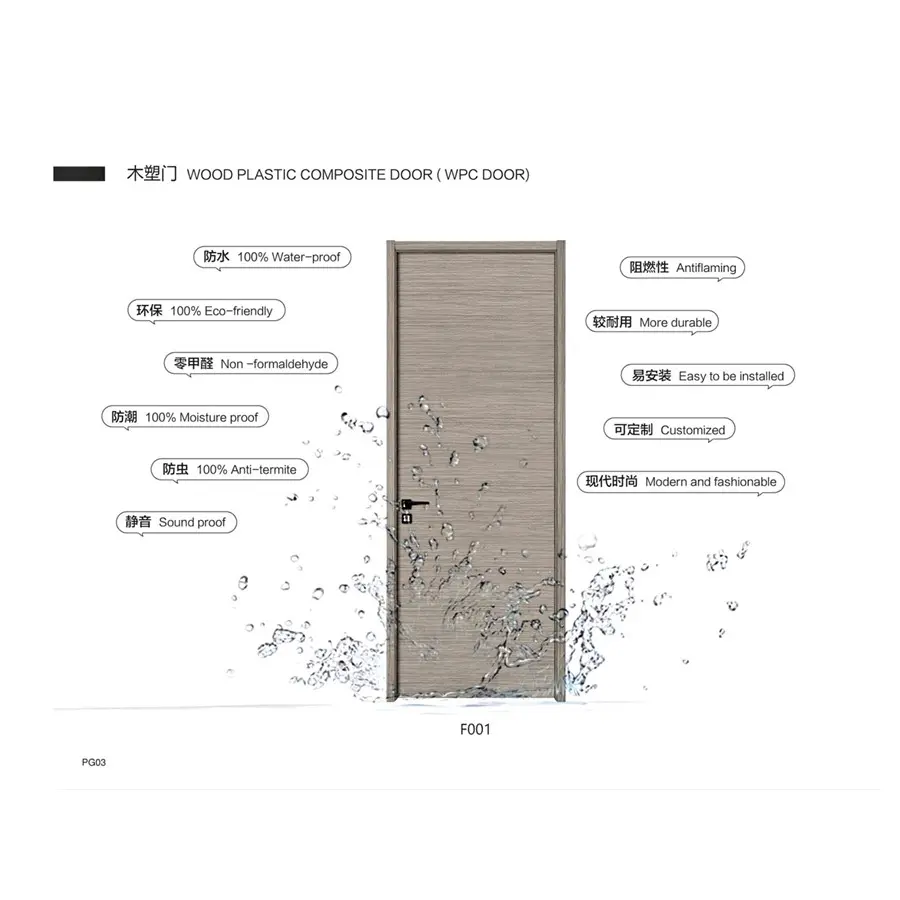

The waterproof and moisture-proof code for wood-plastic doors: Secure locking even in damp Spaces

In scenarios with persistently high humidity such as bathrooms, kitchens, basements, and coastal residences, Wooden Doors are prone to warping and metal doors are likely to rust. However, wood-plastic doors are often the first choice for designers. Its waterproof and moisture-proof capabilities are not just a marketing slogan, but a hard-core answer jointly written by material science, structural design and process details.

First, Materials: The "Symbiosis" of Wood Fibers and Polymers

The base material of wood-plastic doors is made by blending 60% recycled wood fibers with 40% high-density polyethylene or polypropylene, and then formed through high-temperature extrusion. Wood fibers offer a natural texture and nail-holding power. The high-molecular coating of wood fibers forms a continuous hydrophobic network, with a water absorption rate of less than 0.5%, which is far lower than the standard of 8% to 12% for solid wood. The coupling agent added to the resin makes the wood fibers and plastic "hand in hand", preventing water from seeping through the capillary pores of the fibers.

Second, structure: Three layers of barriers keep water out layer by layer

Surface co-extruded ASA film: Resistant to ultraviolet rays and acids and alkalis, surface contact Angle >100°, water droplets roll off immediately upon touch.

Middle layer closed micropores: The foaming process introduces uniform microbubbles, which not only reduces weight but also blocks the lateral migration of water.

Bottom layer bidirectional reinforcing ribs: Trapezoidal ribs increase flexural strength and prevent water seepage caused by micro-cracks due to temperature differences.

Third, process: Make the "gaps" waterproof as well

Mortise and tenon hot melt welding: The corners of the door frame are welded at 45° high-frequency, and the weld seam is integrated with the base material, without any glue seams or nail holes.

Back water channel: A 3mm inverted V-shaped water channel is hidden at the bottom. Condensate water is discharged along the channel without touching the door core.

Hidden sealing strip: The EPDM foam strip is embedded in the stop mouth, with a compression rebound of over 80%, and can resist steam penetration all year round.

Fourth, Testing: From the laboratory to real scenarios

168-hour constant temperature water immersion: The sample is immersed in water at 25 ℃ for 7 days, with a thickness expansion rate of no more than 0.3%.

50 cycles of cold and hot: alternating between -20 ℃ and 70 ℃ for 48 hours, no delamination, no cracking.

Salt spray 720 hours: Simulating a high salt spray environment along the coast, with no rust or mold spots on the surface.

Fifth, tips for use and maintenance

Before installation, ensure that the moisture content of the wall is less than 12% to prevent water vapor from seeping back.

For daily cleaning, neutral detergent is sufficient. Do not use strong acids or alkalis to avoid damaging the surface layer of ASA.

When the temperature difference is large in winter, leave a 2-mm ventilation gap at the bottom of the door to prevent the accumulation of condensation water.

If there is long-term contact with accumulated water on the ground, a stainless steel ground sill can be installed to form a secondary water barrier.

From the material formula to the microstructure and then to the entire door craftsmanship, the "waterproof and moisture-proof" features of wood-plastic door handles are incorporated into every grain. The steam from the bathroom, the fumes from the kitchen, the moisture from the basement and the salt spray from the seaside are all just everyday backgrounds in front of it, not fatal threats. Choosing wood-plastic doors is equivalent to equipping a damp space with an all-weather dry guardian.