Multiple Styles of Personalized Non-standard Doors

PRODUCT SPECIFICATION

| Material | Quality cold-rolled steel sheet & stainless steel;

1. Steel security door with stainless steel doorsill 2. Cold-rolled steel security door leaf and frame with heat transfer-printing, which looks natural wood grain (or powder coating). (steel sheet thickness available from0. 5mm~1mm for door leaf, and 1.0mm~2.0mm for door frame) |

| Steel security door lnfilling | Honeycomb |

| Locks and handles | Specialist security lock with more lock points(alternative available) |

| Design | Diversified available |

| Colour | Diversified available |

| leaf thickness | 70mm |

| frame thickness | 120mm-270mm available |

| Size available | 2050*1200 mm as standard size, also can be as per requirement |

| Accessorie | Hinges, locks, handles, viewer (peephole), doorbell, rubber seal, installing bolts ,cover |

| Opening direction | Left or right, Inside or Outside |

| Opening degree | 180 degree |

| Container capacity | 100-148pcs/20Ft, 225-300pcs/40Ft, 275-364pcs/40HQ |

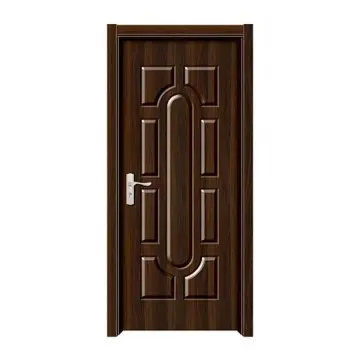

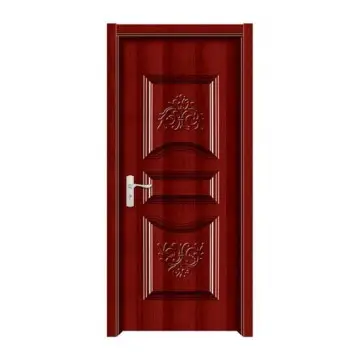

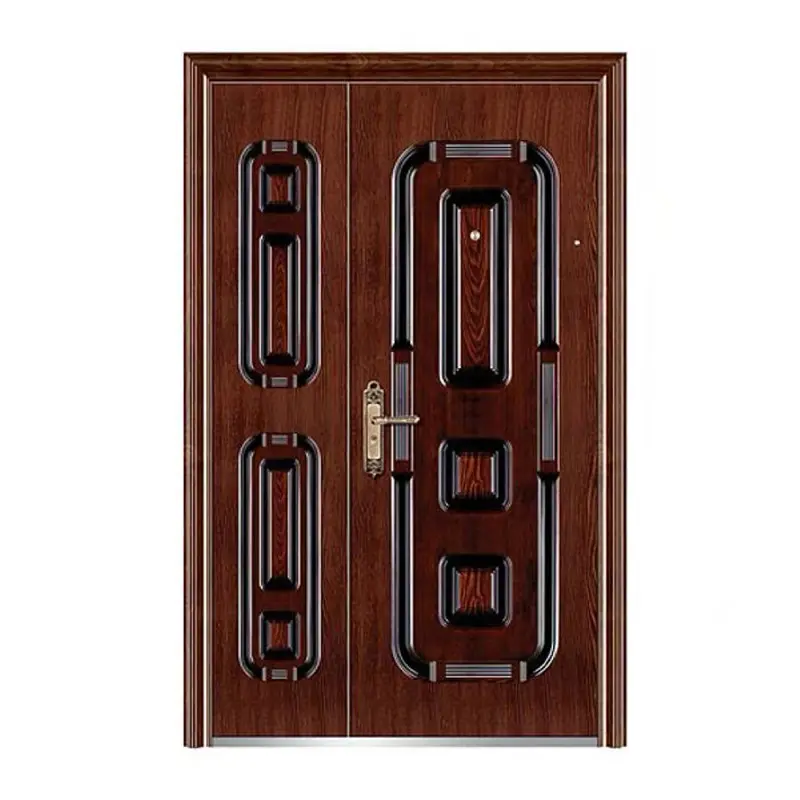

PRODUCT DISPLAY

Non-standard door production process

1. Design:

Design is done first, and detailed door drawings are drawn up based on the customer's needs, site requirements and door usage. The design of the door should consider the shape, material, color, decoration, etc. of the door.

2. Select materials:

According to the purpose and design requirements of the door, select suitable materials for production. Commonly used door materials include solid wood, artificial panels, aluminum alloy, stainless steel, steel plates, glass, etc. When selecting materials, attention should be paid to requirements such as fire protection, anti-theft, and thermal insulation.

3. Processing:

After the door material is selected, it is processed. Processing includes material opening, cutting, shaping, polishing and other processes. Cutting and cutting require the use of professional processing equipment, and shaping and polishing require experienced technicians.

4. Painting:

The painting of non-standard doors generally includes primer, topcoat, glazing and other processes. Painting requires a certain technical level, and attention needs to be paid to the quality and thickness of the paint during the painting process.

5. Installation:

After the non-standard door is processed, it needs to be installed. During the installation process, the door and door frame need to be matched, and site survey and installation location need to be determined before construction. During the installation process, it needs to be fixed according to the requirements to ensure the stability and safety of the door.

How to install non-standard doors

Before Installation

1. Check whether the door frame and facade are intact, whether there is any damage, and whether the accessories are complete.

2. Check that the lace is straight. If it is bent, it needs to be adjusted before installation.

3. Check the diagonal line of the mast and adjust the error to within 5 mm.

4. Check whether the upper, middle and lower dimensions of the door opening are consistent, whether the upper, lower, left and right are parallel to the ground and 90 degrees perpendicular to the ground, and whether the ground is flat.

Installation Process

1. When the door frame is put into the door opening, it must be parallel to the top, bottom, left and right. If the door opening is more than one centimeter larger than the door frame, the location where the expansion screws need to be driven must be solidly padded with stones or wood. First, make an expansion screw on the upper left and lower right side of the door frame. Do not tighten the screws.

2. Hang the facade and check whether the gap between the facade and the door frame is parallel and whether the size is standard. Whether the two door surfaces of the double door are in a straight line. The gap between the main and auxiliary doors in the middle should not be greater than 5 mm. Check whether the opening and closing are smooth.

3. After adjustment, take off the door and put on the other screws. When tightening the screws, tighten them one by one from left to right and up and down several times. The tightness of the screws is subject to the door frame not being pulled.

4. Hang the door back and recheck the gap and opening and closing. If there are any differences, try adjusting the tightness of the expansion screw to adjust the door gap and opening and closing.

5.After fixing, install and fix the handle on the door surface. Do not turn the handle screw too tight.

6. After the installation is completed, drive foam or pour cement into the door frame. You must wait until the door adjustment is completed before performing this operation. During the operation, do not put too much pressure on the door frame to cause the door frame to deform.

Installation precautions

1. The size of the door gap can be adjusted through the hinge gap and the tightness of the expansion screw.

2. The door rebound can be adjusted by tapping the hinge to increase the gap.

3. The door key is not flexible. If the second lock does not return, you should first check whether the key is flexible when opening the door, and then check whether there are foreign objects in the upper and lower lock insertion rod holes. Is the distance between the main and auxiliary doors less than 5 mm when closed?

4. The protrusion in the middle of the ground will cause the upper and lower gears to hit when closing the door.

5. If the door opening is too large, tightening it with expansion screws will cause the distance between the door surfaces to be too large and the lock cannot reach it.

6. The door covering paper should be cleaned within one week after the door is installed.

Selection of non-standard doors

1. Check the performance and structure of the door lock: when purchasing, the rotary lock head will rotate synchronously with the drill bit to prevent the lock head from being damaged. The lock requires synchronous rotation in three directions to prevent the lock head from being damaged. Generally, locks It requires a three-way locking structure, three hinges for a single door, six hinges for a double door, and a hidden lock on the door leaf and door frame. Even if the hinges are destroyed, the door cannot be opened.

2. Check the number of locks on the door and the number of poles: You can choose 2 locks, each of which controls 2 poles. Even if the door is damaged, it will delay the door. Generally, a lock can control 3 to 4 poles. This kind of door has poor anti-theft properties. If the lock is damaged, the insertion rod will lose its function at the same time.

3. Look at the thickness and area of the reinforced version around the lock: Structurally, non-standard doors are divided into two types: closed type and fence type. No matter which one you choose, the lock is the main part of theft and damage, so the thickness of the lock core guard exceeds 2 mm. Cold steel plate, the height of the core plate shall not be less than 500 mm.

4.Check the quality of the workmanship: The quality of the production process of non-standard doors is very critical. Pay attention to check whether there are welding defects, such as missing welds, missing welds, slag inclusions, etc. You should also check whether the door leaf and door frame are tightly matched and whether there are gaps. Uniform, whether the opening is flexible, whether the paint plating is uniform, firm and smooth, etc.

5. Choose from the appearance design: Non-standard doors are divided into three types: luxury, mid-range and ordinary. Consumers can choose the appropriate type according to their personal circumstances.

COMPANY PICTURES

Certificate