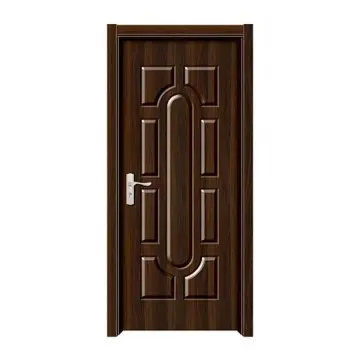

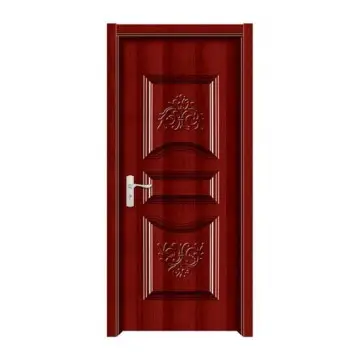

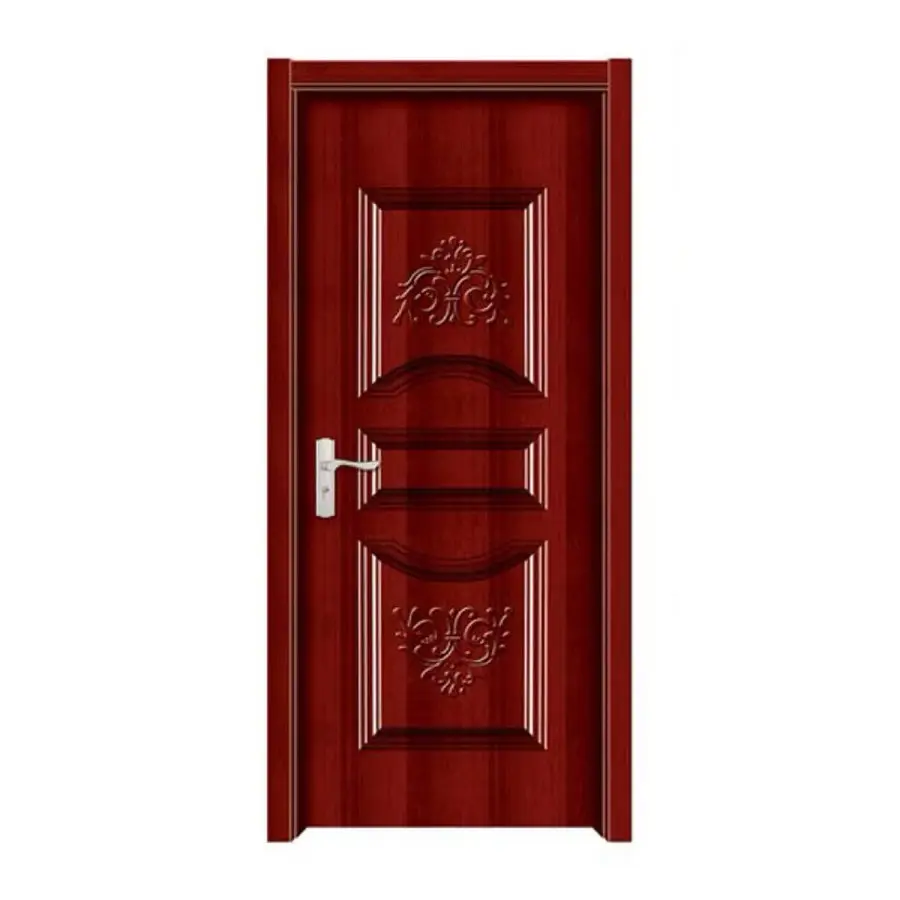

Melamine Decorative Interior Wooden Doors

Product details

| Material | MDF/HDF |

| Size | Length: 1900mm-2150mm

Width: 600mm-1050mm Thickness:35mm-45mm |

| Density | >850g/cm3 |

| Moistuer | 6%~10% |

| Finish Type | Finished |

| Shipment | Within 45-60 days after receiving the deposit |

| Packing Detail | 70PCS/Pallet |

Advantages of Melamine wooden door

1. Paint-free and environmentally friendly: The melamine wooden door uses environmentally friendly adhesive and has a melamine molded layer of various colors or natural wood grains on the surface. There is no need to cut down the original trees to meet the user's demand for natural wood. The amount of formaldehyde released and harmful The heavy metal contents are all lower than the national standards.

2. Beautiful and wear-resistant: The surface is paint-free, environmentally friendly, waterproof, flame retardant, wear-resistant, pollution-resistant and has various colors or natural wood grain effects, making it beautiful and elegant.

3. Fireproof and durable: It has good fireproof performance and can effectively protect family safety.

4. Good environmental performance: does not contain harmful substances and is harmless to human health.

5. Good flame retardant performance: Melamine wooden doors have excellent flame retardant properties. When a fire occurs, the material will not melt or produce burning droplets, but will only carbonize and produce a small amount of smoke.

6. Shock absorption and compression resistance: Melamine foam has a unique three-dimensional network cross-linked structure and has good shock absorption and compression resistance.

7. Good environmental performance: No harmful substances such as Freon are used in the production process, and they can be recycled to reduce resource waste and environmental pollution.

Production process of melamine wooden door

1. The base material is medium density board, and the base material is 18mm medium density board, with white melamine paper pasted on both sides;

2. Carry out engraving and milling according to the door type selected by the customer;

3. After the engraving and milling is completed, apply sealing paint on the leaky bottom part;

4. Sand and spray white primer;

5. 2 times of polishing for coloring;

6. Repeat 8-9 times of grinding, polishing and spraying;

7. Finally, spray varnish;

8. Water polishing;

9. Polish with polishing wax;

10. If the process is in place, the adhesion of the covered paint film will be very strong, not easy to fall off, and the paint film will be full;

11. Fixed packaging.

About us

Company system: The company has introduced complete sets of advanced production technology and equipment, and has successively established a product research institute, technology development department, quality inspection center, sales center, after-sales service department, etc.

CAD design: All products are designed by CAD, operated on modern anti-pry lines, and tested by advanced production testing equipment.

Talent introduction: The company will spend a lot of money to recruit talents every year, expand the scale of production and operation, further explore foreign markets, and continue to develop a series of anti-theft products with steel doors as the main line to meet social needs.

Certificate