High Strength and High Security Steel Standard Door

PRODUCT SPECIFICATION

| Material | Quality cold-rolled steel sheet & stainless steel;

1. Steel security door with stainless steel doorsill 2. Cold-rolled steel security door leaf and frame with heat transfer-printing, which looks natural wood grain (or powder coating). (steel sheet thickness available from0. 5mm~1mm for door leaf, and 1.0mm~2.0mm for door frame) |

| Steel security door lnfilling | Honeycomb |

| Locks and handles | Specialist security lock with more lock points(alternative available) |

| Design | Diversified available |

| Colour | Diversified available |

| leaf thickness | 50mm, 70mm, 90mm or client's demand |

| frame thickness | 80mm-270mm available |

| Size available | 2050*1200 mm as standard size, also can be as per requirement |

| Accessorie | Hinges, locks, handles, viewer (peephole), doorbell, rubber seal, installing bolts, cover |

| Opening direction | Left or right, Inside or Outside |

| Opening degree | 90degree,180 degree |

| Container capacity | 100-148pcs/20Ft, 225-300pcs/40Ft, 275-364pcs/40HQ |

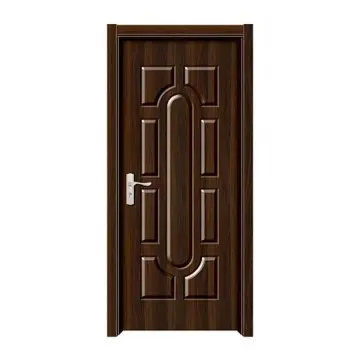

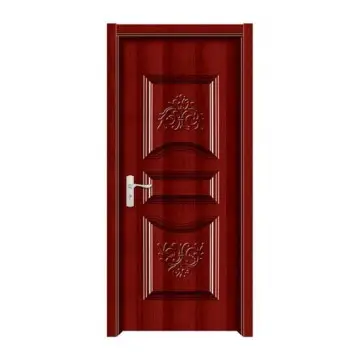

PRODUCT DISPLAY

The quality standards of steel doors include the following aspects

1.Material standards. Door frames are usually made of high-quality hot-melt galvanized steel sheets (such as SGCC) with a thickness of ≥1.5mm. The door leaf material is also made of galvanized steel plate, the thickness is generally 0.6~0.8mm, and the door leaf thickness is usually 40mm.

2.Surface treatment: Surface treatment usually uses polyester material, which is sprayed by electrostatic polyester. The coating thickness is ≥60um, and the base material needs to be antibacterial treated.

3.Filling material: The interior of the door leaf is usually filled with high-strength honeycomb paper or similar materials. Filling material that is non-toxic, harmless, fireproof and heat-insulating, and meets environmental protection requirements and regulatory requirements. The steel fire door leaves are filled with perlite fireproof materials, and the door frames are filled with cement fireproof materials; all fillers must provide a test report issued by the relevant national department;

4.Sealing requirements: The door frame is equipped with a sealing groove (between the door frame and the door leaf, and between the door leaf and the door leaf). Fire-resistant and flame-retardant fire-proof expansion tape is embedded in the groove. The expansion performance of the fire-proof expansion tape must be tested and qualified by the relevant national department. Report;

5. When the door is closed, the door leaf and the door frame fit together. The gap on both sides between the door leaf and the door frame is not greater than 3mm. The upper gap is not greater than 3mm. The gap in the middle gap of the double door is not greater than 3mm. The gap between the door leaf and the lower frame or the ground is not greater than 3mm. It should not be larger than 9mm; the flat structure double-leaf fire door is equipped with a cover seam plate, which is firmly connected to the door leaf and does not affect the normal opening of the door leaf.

6. The door frame adopts an overall single-notch structure. The bent air-tight pressure groove and the door frame are formed at one time from a steel plate. They are automatically positioned through CNC bending, which has high strength and accurate positioning. The door frame adopts an inlaid air-tight strip structure, which is noise-free when opening and closing. , good air tightness;

The appearance of steel doors on the market is very similar to that of anti-theft doors. In terms of anti-theft performance, standard anti-theft doors have thick steel plates, strong impact resistance, and comply with national mandatory standards; while steel doors comply with each company's own corporate standards. Steel doors are widely used indoors and outdoors in various buildings. Steel doors used for outdoor use are generally made of steel doors with multiple uses. They need to use galvanized steel plates, each reinforcement is welded and strengthened with oxygen shielded welding, and a waterproof threshold (or bottom seal), anti-theft pin, and UV resistance are installed. High-quality coating to adapt to harsh outdoor working environments exposed to the sun and rain.

Factory Display

Certificate