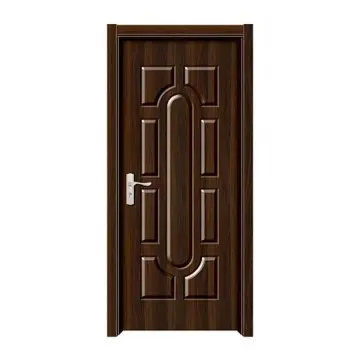

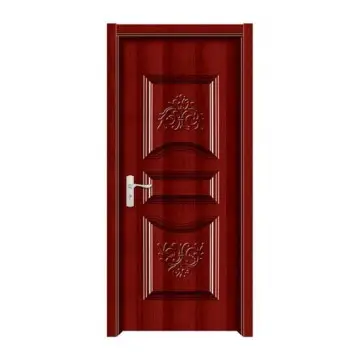

HDF+ PU Molded Doors with Multiple Colors Available

PRODUCT SPECIFICATION

| Material | Surface: PVC skin

HDF Panel thickness: 6mm/8mm/12mm available Structure: Frame: Solid wood core+ MDF Inside filling Door leaf: Solid wood core, both sides with HDF panel Solid wood/honeycomb |

| Standard size | 2050*900/2030*860 |

| Door leaf hickness | 35mm/40mm/45mm |

| Opening | Swing, sliding, folding |

| Color | Reference to our color card |

| Accessories | Lock, hinge, handle, glass |

| EnvironmentalStandards | Europe E1, Environment Friendly |

| Daily Capacity | 500sets |

| Packing Details | E film, Bubble plastic bag, strong carton |

| Lifetimecs | At least 6 years |

| Door Surface design | Diversified available |

What material is the film of the molded door made of?

The membrane of molded doors is mainly PVC membrane. The molded door panel uses medium density board (MDF) or high density board (HDF) as the base material, and the surface is decorated with natural solid wood veneers such as ash, black walnut, rosewood and sapele, or PVC or PP film. The film of the molded door panel can also be directly made of PVC film without any veneer or skin. In addition, the membrane of the molded door panel can also be a PVC membrane. This kind of membrane has a high cost performance, diverse appearance, can be made into various shapes, and has the advantages of no cracking, no deformation and waterproof.

The molded door is made of MDF or high-density board as the frame, and a layer of PVC film is attached to the surface for hot pressing and molding. This kind of door has a uniform internal structure, is not easily deformed, has a smooth surface and has various shapes. The molded door is made of artificial forest wood, which is peeled, sliced, screened, and ground into dry fibers. After being mixed with phenolic glue as a binder and paraffin, it is molded in one step under high temperature and pressure. The panel of the molded door is veneered with wood and painted with varnish, which maintains the decorative effect of the natural texture of the wood. At the same time, it can also be paneled, which is beautiful, lively, economical and practical. Molded doors are also plywood doors, but the panels of the molded doors are made of high-density fiber molded door panels.

Introduction to the advantages of molded doors

1. Green and environmentally friendly

Molded doors are relatively green and environmentally friendly. Phenolic resin is added during the production process. This material is the adhesive of the molded door panels. It does not contain free formaldehyde that is harmful to the human body, allowing people to have a more comfortable living environment.

2. Quality stability

Compared with those natural woods, molded doors have the characteristics of dense texture, no cracking, no deformation, no expansion, no shrinkage, no warping, etc., and their performance is more stable.

3. Good wear resistance and heat resistance

When we cook food, we produce a lot of fumes, and it is easy to scratch the cabinets when using knives. This type of door panel has good wear resistance and heat resistance, will not crack or deform, and is easy to maintain on a daily basis. It can be said that molded door panels are a relatively mature cabinet material on the market. If you choose a European or pastoral style decoration design for your home, molded cabinet door panels are a good choice.

About us

Certificate