Environmentally Friendly Silent High-Strength WPC Skin Doors

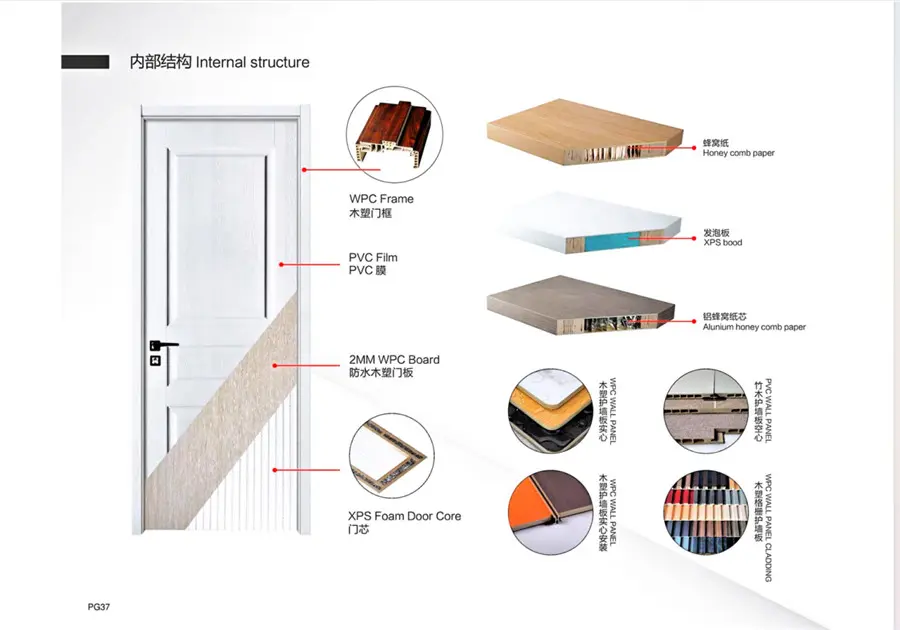

The core advantages of KARELA wood plastic doors

1.High-quality raw materials and scientific formula. The main raw materials of KARELA wood-plastic doors are PVC resin and high-quality wood powder. The PVC resin uses medical grade domestic famous brand products. The wood powder is provided by professional wood industry companies as high-quality tree species wood powder. After graded screening, processing, drying and coating treatment, Ensure the finished product meets raw material quality requirements. The wood-plastic door formula system is equipped with a certain proportion of auxiliary materials, including stabilizers, foaming agents, modifiers, etc. The various ingredients are mixed in strict proportions to effectively ensure the product quality of wood-plastic boards.

2. Advanced manufacturing of electronic equipment. The manufacturing electronic equipment, from the mixing system to the extrusion system, is all imported from abroad. It is at the international leading level and has a high degree of automation. Among them, the mixing electronic equipment has the characteristics of accurate dosage of ingredients, even mixing and distribution, and high efficiency, which fundamentally ensures the product quality. stability. Since the manufacturing of wood-plastic doors has high requirements on extrusion electronic equipment, a high-torque twin-screw extruder was used, and the screw, barrel and other components were modified to adapt to the skinning on the inner and outer surfaces of the lignin and the uniform distribution of plastic, to prevent wood powder carbonization and other phenomena from happening again.

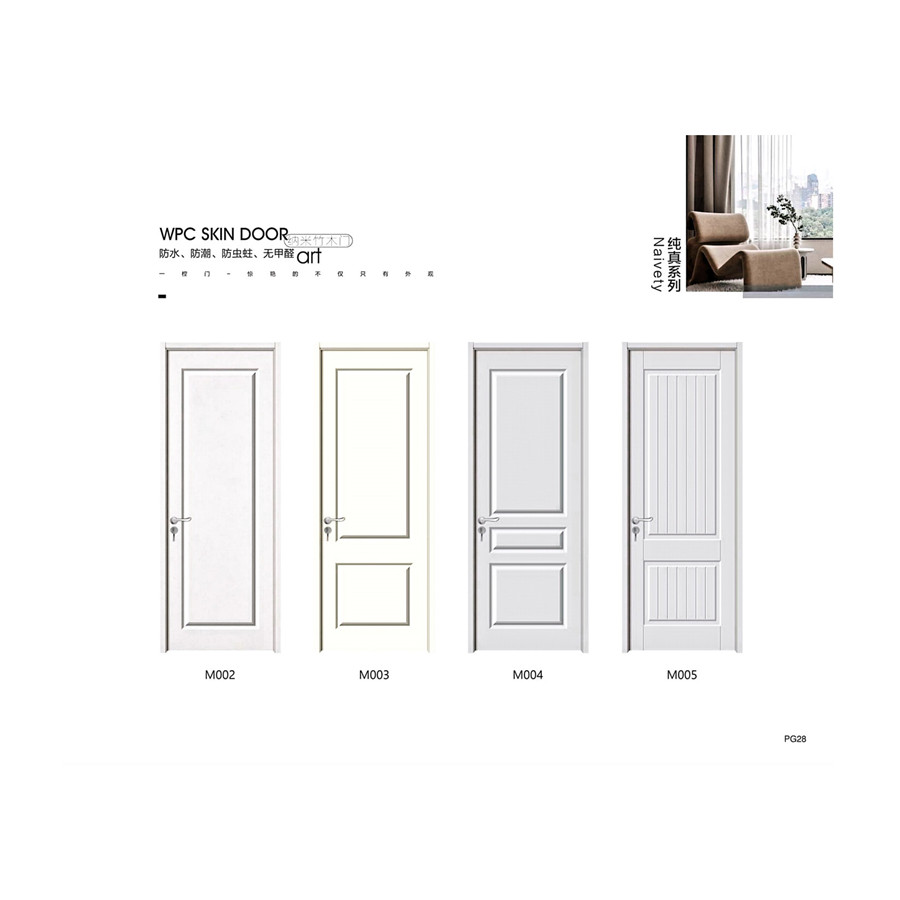

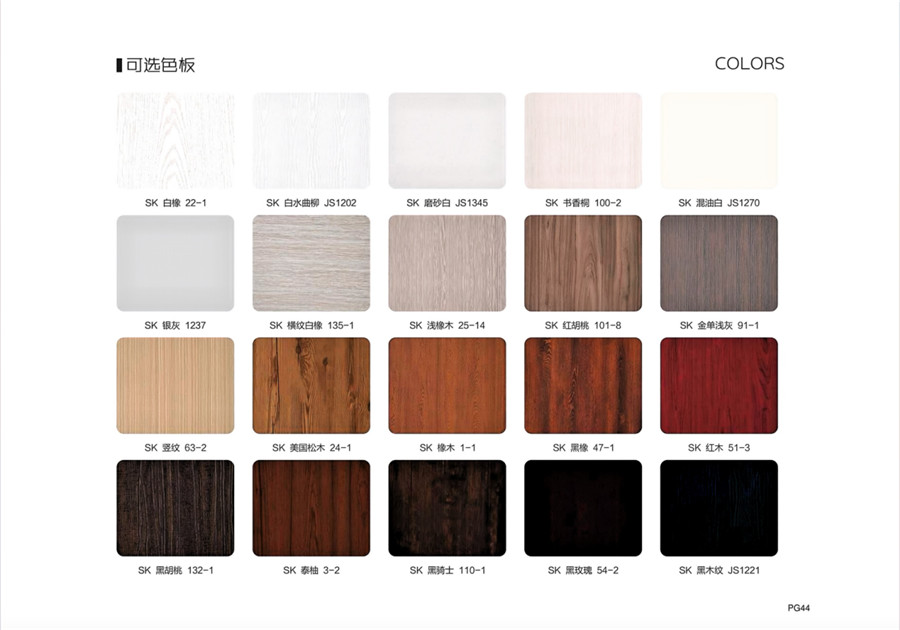

3. Thermal transfer technology. We are the first to use thermal transfer printing technology to transfer various graphics on extruded boards, so that the products have a variety of high-end tree species wood grains and colors. According to the popular varieties in the market, we have designed black walnut, ivory white, wax elephant wood, etc. A variety of finishes are available for customers to choose freely, and more than 100 interior door designs are provided to meet the market needs of modern consumers' life styles.

4. Green and environmentally friendly. The raw materials used in KARELA wood-plastic set doors are formed in one step under high temperature, high pressure, and vacuum conditions. The materials do not contain formaldehyde. Thermal transfer printing technology is used as secondary raw materials, which is paint-free. There are no highly toxic and hazardous gases and gases during the manufacturing and use processes. The odor is released and it is a human-friendly product that meets the environmental protection standards of modern interior decoration.

5. Good thermal insulation and sound insulation performance. The materials used in KARELA wood-plastic set doors have evenly distributed, fine cells and a specially designed cavity structure, which ensures that the thermal conductivity is lower than ordinary plastic materials and the noise reduction performance is good.

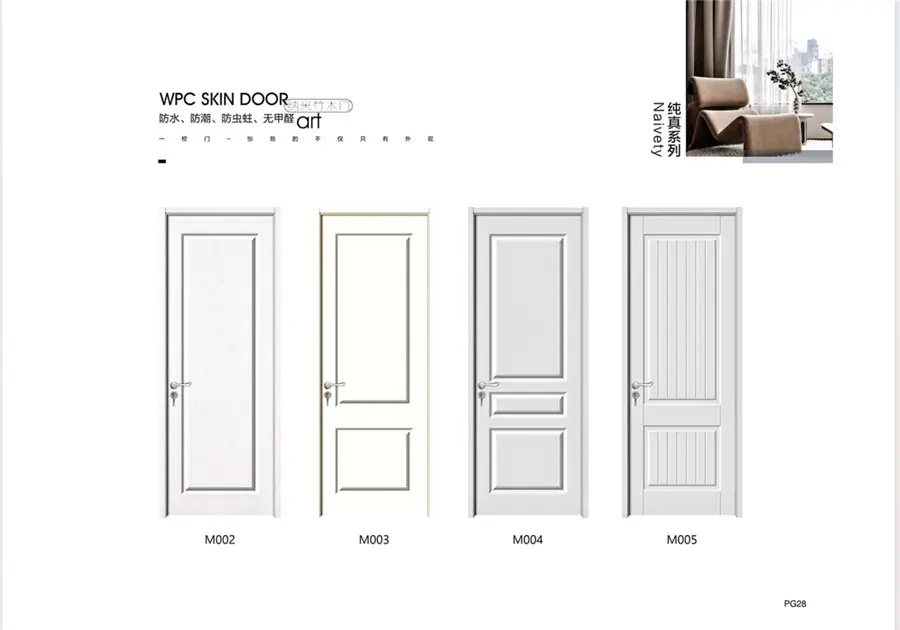

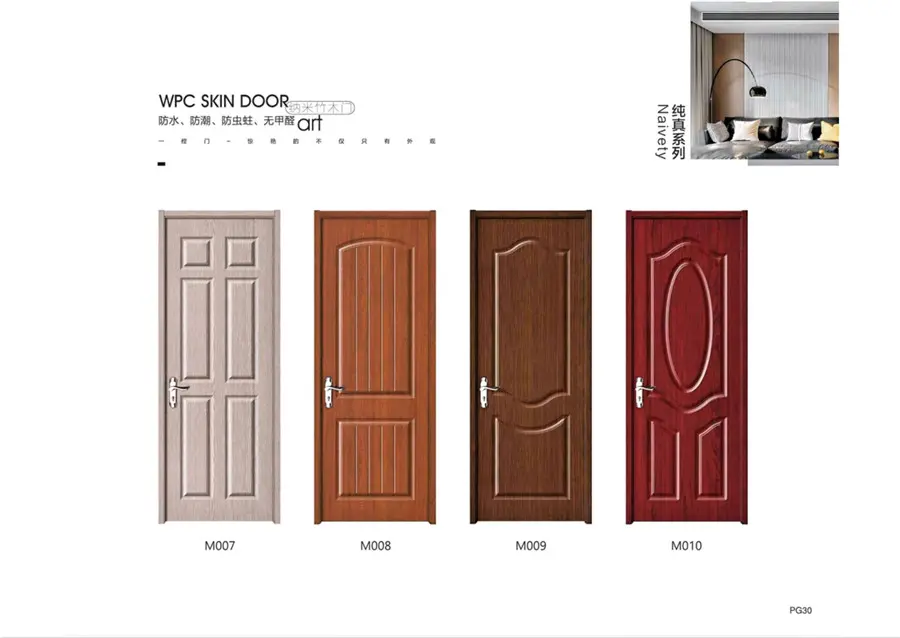

PRODUCT DISPLAY

ABOUT US

Certificate