Environment Friendly PVC MDF Interior Doors

Product details

| Material | Surface: Good quality PVC skin +Aluminum line

HDF Panel thickness: 8mm/12mm available Structure: Frame: Solid wood core+ MDF Inside filling Door leaf: Solid wooTd core, both sides with HDF panel Solid wood/honeycomb |

| Standard size | 2050*900/2030*860 |

| Door leaf hickness | 40mm/45mm |

| Opening | Swing, sliding, folding |

| Color | Reference to our color card |

| Accessories | Lock, hinge, handle, glass |

| EnvironmentalStandards | Europe E1, Environment Friendly |

| Daily Capacity | 500sets |

| Packing Details | E film, Bubble plastic bag, strong carton |

| Lifetimecs | At least 6 years |

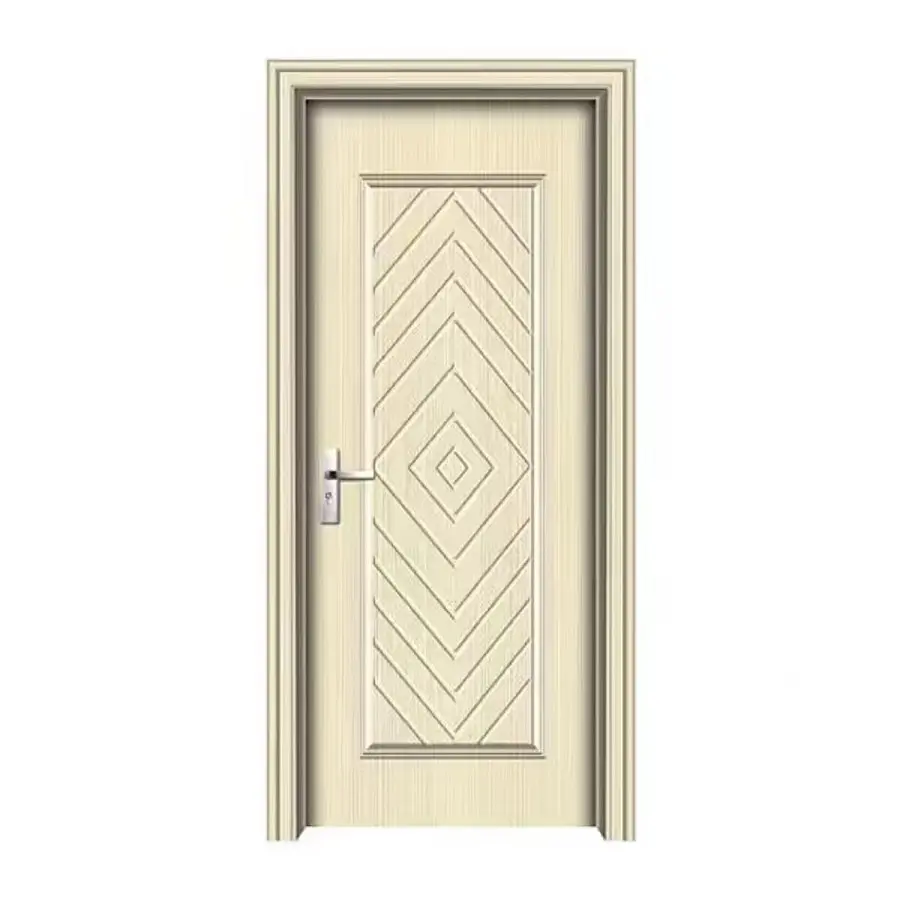

| Door Surface design | Diversified available |

Classification of PVC MDF interior doors

By door skin type

1.Solid wood veneer molded door panel

Solid wood veneer molded door panels refer to molded door panels with natural wood veneers on the surface such as ash, black walnut, rosewood and sapele. It is the mainstay of molded door panels and is dominated by its ecological composite solid wood doors. More than 50% of the entire door industry consumer market.

2.Melamine molded door panel

This melamine is not the other melamine. The other melamine became notorious after it was added to milk and harmed children. However, this melamine is popular in the production of low-end ecological doors. Melamine molded door panels specifically refer to molded door panels with melamine paper on the surface. It is characterized by its relatively cheap cost and is suitable for low-quality project decoration requirements. It has been gradually fading out of the market.

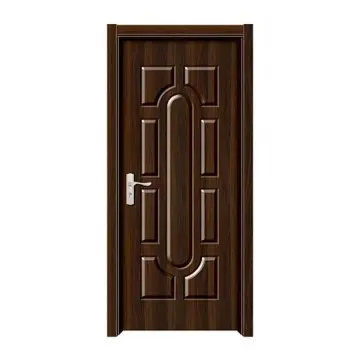

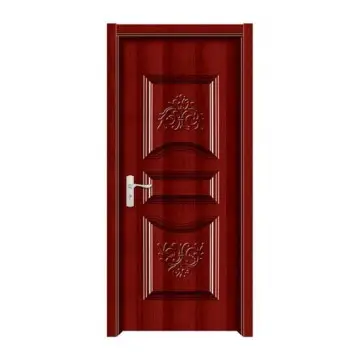

3. Plastic steel molded door panel

Plastic steel molded door panels refer to PVC steel-wood door panels that use steel plates as the base material, are pressed into various patterns, and then blister-molded. This type of door panel looks very solid and occupies a certain share of the market. It is suitable for outdoor doors and is deeply loved and chosen by some consumers.

According to production process

1. One-time molded door panel

One-time molded door panel refers to a door panel produced by the door panel technology that only needs to be pressed once with a mold during the production process. The process is relatively simple and can save production costs. However, the quality of the finished product is relatively poor and the blistering phenomenon is more than two times. Secondary molded door panel.

2. Secondary molded door panel

Secondary molding molded door panels refer to molded door panels that are produced by first embossing medium-density board (MDF) or high-density board (HDF), then manually applying veneer to the surface, and then performing a second embossing process. It has the advantages of being deeper than one-shot molded door panels, less blistering than one-shot molded door panels, and more stable quality of finished products than one-shot molded door panels.

Things to note when purchasing PVC MDF Interior Doors

1. Material quality: Be sure to choose good quality PVC films and MDF sheets to avoid cracking due to quality problems.

2. Production technology: Try to choose manufacturers with advanced production technology and standardized process flow to ensure product quality.

3. Color matching: The surface of molded door cabinets has a variety of colors and textures. The color and texture should be selected based on the actual situation.

4. Dimensions and specifications: When purchasing molded door cabinet doors, you should measure the dimensions according to the actual situation and choose the appropriate specifications and sizes.

5. After-sales service: Try to choose a manufacturer with complete after-sales service, so that if quality problems arise, they can be dealt with in a timely manner.

About us

Certificate

F&Q

1. What is the MOQ of your products?

The MOQ is 200 pieces

2. What’s your quality guarantee?

Our products have acquired the ISO9001 Quality System Certificate, and the tire department has acquired the CCC Certificate. Moreover, many kinds of products have acquired the GS/TUV Certificate, ISO14001, FSC.