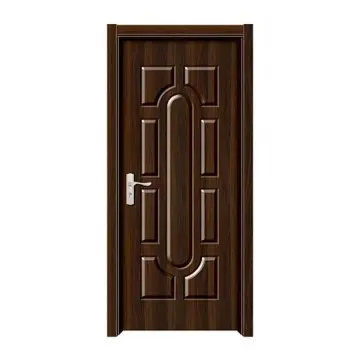

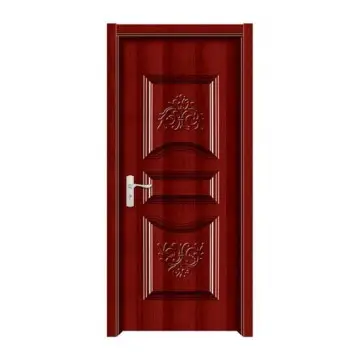

Anti-Corrosion, Wear-Resistant and Silent Steel Standard Door

PRODUCT SPECIFICATION

| Material | Quality cold-rolled steel sheet & stainless steel;

1. Steel security door with stainless steel doorsill 2. Cold-rolled steel security door leaf and frame with heat transfer-printing, which looks natural wood grain (or powder coating). (steel sheet thickness available from0. 5mm~1mm for door leaf, and 1.0mm~2.0mm for door frame) |

| Steel security door lnfilling | Honeycomb |

| Locks and handles | Specialist security lock with more lock points(alternative available) |

| Design | Diversified available |

| Colour | Diversified available |

| leaf thickness | 50mm, 70mm, 90mm or client's demand |

| frame thickness | 80mm-270mm available |

| Size available | 2050*1200 mm as standard size, also can be as per requirement |

| Accessorie | Hinges, locks, handles, viewer (peephole), doorbell, rubber seal, installing bolts ,cover |

| Opening direction | Left or right, Inside or Outside |

| Opening degree | 90degree,180 degree |

| Container capacity | 100-148pcs/20Ft, 225-300pcs/40Ft, 275-364pcs/40HQ |

About the lock cylinder

Processing requirements for steel standard doors

1) The width of the door frame is the designed opening width minus 3 cm. The height of the door frame of a fire door with a lower frame is the design opening height minus 2 cm. The height of the door frame of a pre-embedded fire door is the same as the designed opening height (the door frame is 2 cm pre-embedded);

2) Strengthen door corners as required to avoid twisting or sagging;

3) The exposed surface of the steel door and door frame has no warps, twists, wrinkles, visible bumps, scratches or other defects. The door corners are square, all solder joints are firmly welded, the solder joints are evenly distributed, the weld joints are flat and smooth, and no false welds are allowed. or burn-through phenomenon, the plug welding part on the outer surface should be smooth;

4) Steel pipe well fire doors adopt pipe well door locks;

5) The topcoat on the surface of the standard steel door must be uniform, flat, and smooth, and there must be no paint build-up, pitting, bubbles, leakage, or bleeding;

6) The opening size and opening direction of the steel standard door are based on the actual construction plan.

Steel standard door installation requirements

1. Before formal production and installation, the door position and quantity should be carefully reviewed, and the actual dimensions of the door to be produced should be reviewed and confirmed before production.

2. Marking and positioning: According to the size, elevation and opening direction specified in the design drawing, mark the installation position line of the door frame in the opening. Vertical frame correction: After the door frame is in place, its verticality (the door frame is not perpendicular to the ground, should be ≤ 2°), horizontality and diagonal should be corrected, and adjusted to the installation height according to the design requirements, consistent with the interior and exterior walls. The distance is the same and the width of the door frame is the same up and down. Connection and fixation: The door frame is temporarily fixed with bolts and must be reviewed to ensure accurate installation dimensions.

3. When installing the door, install the door leaf to the door frame and adjust its position and level.

4. Door frame installation: Before the door frame is installed, on-site dimensional measurements must be carried out, and the drawings and related design changes must be proofread, reviewed and technically explained to determine the opening direction. The installation of the door frame must strictly comply with the design and related regulatory requirements. According to the different structures of the door frames, fill all the gaps around the door frames with cement mortar and fix them with the wall through connectors (wall fittings). The installation method of the tube well door is: flush with the finished surface of the exterior wall; the installation method of other fire doors is mid-mounted.

5.Installation of door leaves and hardware accessories: Before construction, the notch of the door frame should be carefully checked, and no foreign matter should be allowed to remain. The glue joints should be horizontal and vertical to maintain the overall consistency. The hardware accessories should be installed firmly, not loose, and open flexibly.

Factory Display

Certificate